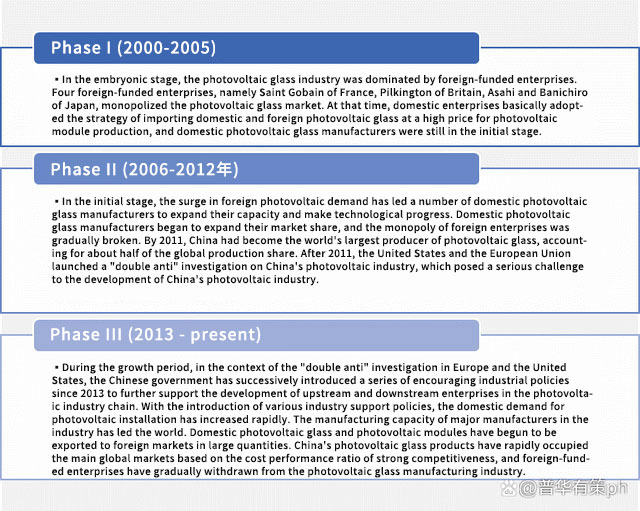

In China, the development history of photovoltaic glass industry can be roughly divided into three stages.

Source: Puhua Youce

1. Development trend of photovoltaic glass industry

(1) Photovoltaic Building Integration (BIPV)

Building Integrated Photovoltaic (BIPV) is a new technology to install the solar photovoltaic power generation array on the exterior surface of the building envelope to provide power. As a new application field of green, low-carbon, environment-friendly and energy-saving photovoltaic products, PV building integration can not only meet the functional requirements of photovoltaic power generation, but also take into account the functional and aesthetic requirements of buildings, provide customers with stable renewable energy and long-term economic benefits, and is a combination of photovoltaic products and building materials. PV building integration can greatly improve the efficiency of resource use, and the broad PV building integration market will become the next vent of PV glass.

(2) High light transmittance

The core development goal of the entire photovoltaic industry is to continuously reduce costs and improve efficiency and continuously reduce the cost of electricity. With the continuous development of high efficiency battery technology and high efficiency module technology, photovoltaic glass as module packaging material has been required to have higher and higher light transmittance. In order to reduce the cost per kilowatt hour as much as possible and improve the power of modules, downstream module manufacturers require that the higher the light transmittance of panel glass packaged as modules, the better. At present, photovoltaic glass manufacturers mainly improve the light transmittance of photovoltaic glass through coating technology.

(3) Special functionality

Special functional glass refers to photovoltaic glass for special purposes, such as photovoltaic glass with anti glare function used in airports, and photovoltaic glass with anti sand function used in deserts. With the diversification of photovoltaic glass use scenarios, downstream customers have different requirements for special functions of photovoltaic glass, so photovoltaic glass manufacturers are required to have the ability to produce differentiated special function photovoltaic glass.

(4) Thinness

With the continuous development of high efficiency battery technology and high efficiency module technology, the technology trend of thinned photovoltaic glass, as the material of module panel and backplane, is becoming more and more obvious. Thin photovoltaic glass refers to the photovoltaic glass with a thickness of 1.6mm2.5mm. Thin photovoltaic glass is characterized by light weight and high light transmittance, and can reduce the cost of photovoltaic modules. Lightweight modules and thin photovoltaic glass have become the industry trend.

(5) Oversize

With the rapid development of modules, the size of the battery chip has developed from the traditional 156mm to the large size of 166mm, 182mm and 210mm, and the corresponding glass size has also increased. The large size photovoltaic glass meets the demand of the future market for large size modules, and meets the demand of module manufacturers to further reduce the cost of electricity. Large size technology of products will be the medium - and long-term technology development direction of photovoltaic glass industry in the future.

(6) Double vitrification of components

In recent years, the rapid development of China's photovoltaic industry has accelerated the technological iteration of photovoltaic glass industry. In view of the advantages of long life cycle, better heat dissipation, flame retardancy, environmental protection and other advantages of double glass modules compared with traditional single glass modules, the penetration rate of double glass modules in the industry has continued to increase in recent years, and it is expected that the penetration rate of double glass modules will further increase in the future. Double glass modules require double area of photovoltaic glass to meet the needs of double-sided power generation. With the gradual increase of its permeability, the demand for photovoltaic glass will also increase significantly. According to the statistics and prediction of China Photovoltaic Industry Association, the penetration rate of double glass modules will continue to increase in the future, which will exceed 60% in 2025, and the compound annual growth rate will exceed 16.47%.

2. Opportunities and challenges faced by photovoltaic glass industry

(1) Opportunities

A. Good industrial policies bring new opportunities for the development of photovoltaic glass industry

China will increase its national independent contribution, adopt more effective policies and measures, strive to reach the peak of carbon dioxide emissions by 2030, and strive to achieve carbon neutrality by 2060. Since 2021, Chinese government departments have issued a series of policies and regulations related to renewable energy such as solar energy to address the problem of insufficient energy supply and promote the rapid development of the photovoltaic industry. The above regulations and favorable policies will bring new opportunities for the development of photovoltaic glass enterprises.

B. The global energy structure has been adjusted and the market demand has continued to grow

In addition to China, many countries and economies, such as Europe, America, Japan and South Korea, have also successively proposed the goal of achieving "carbon peak, carbon neutral". The sustainable policy support and the competitiveness brought by the declining electricity price have made the development of renewable energy to an unprecedented strategic height, and the growth of the global photovoltaic market has been further accelerated. The PV industry has huge incremental space, and has the potential to develop from the current auxiliary energy to the main energy to promote the global energy structure adjustment.

C. Technological progress promotes the rapid development of the industry

The improvement of glass process mainly focuses on improving the cost performance of products. In recent years, with the improvement of photovoltaic glass tempering, coating and glazing technologies, the thickness of photovoltaic glass gradually decreases from 4.0mm to 2.0mm without affecting the strength. The continuous decline of photovoltaic glass thickness drives the continuous decline of glass manufacturer's glass cost per square meter. At the same time, thinner photovoltaic glass products are also conducive to the rapid construction and installation of downstream. The improvement of the deep processing technology of photovoltaic glass has also driven the significant improvement of the core attributes of photovoltaic glass, such as light transmittance and weather resistance, and the deployment area of photovoltaic equipment has been further expanded. A series of technological progress in recent years will drive the development of photovoltaic glass products towards higher light transmittance, lighter and thinner, higher strength, longer life, easier maintenance and other directions, help the photovoltaic glass industry quickly adapt to changes in downstream demand, and drive the rapid development of the industry.

(2) Challenges

A. Leading enterprises actively expand production, and market competition continues to intensify

In view of the good prospects of the photovoltaic industry, the leading enterprises in the upstream and downstream links of the photovoltaic industry chain have successively announced plans to expand their production capacity, and Xinyi Solar, Fulet, etc. have also released plans to expand their production, which is expected to further enhance the concentration of the photovoltaic industry. In particular, as 210mm, 182mm and other large-sized cells need to adapt to large-sized photovoltaic glass, photovoltaic module enterprises are actively cooperating with manufacturers with the production capacity of large-sized photovoltaic glass, so new orders will accelerate to concentrate on leading enterprises. As the head enterprises have stronger risk resistance and can better adapt to the changes in downstream demand, the "big to big" industry development pattern will be further stable. Therefore, for photovoltaic glass manufacturing enterprises, the competition in the subsequent market will become increasingly fierce, facing double challenges of business scale and production technology.

B. Power generation capacity restricts industry development

The development of photovoltaic industry is constrained by the sending and absorbing capacity of power generation. In the early years of the western region, after the large-scale photovoltaic construction was put into operation, the power generation capacity was much higher than the local actual power load. At the same time, due to the lack of long-distance large capacity transmission and peak shaving capacity in the western region and the imperfect power market trading mechanism, the surplus power could not be fully transmitted across provinces and regions, forming a "light abandonment phenomenon" During the 14th Five Year Plan period, the hot spot of photovoltaic investment was in the central and eastern regions. With the eastward movement of the hot spot of photovoltaic investment to the south, the long-standing problem of light abandonment in the western region has been alleviated, but it has not been completely solved.

In order to eliminate the phenomenon of light discarding, the Chinese government has introduced a series of policies and measures aimed at improving the transmission and absorption capacity of renewable energy power generation. With the implementation of the policies and measures, the problem of light discarding will be alleviated to a certain extent.